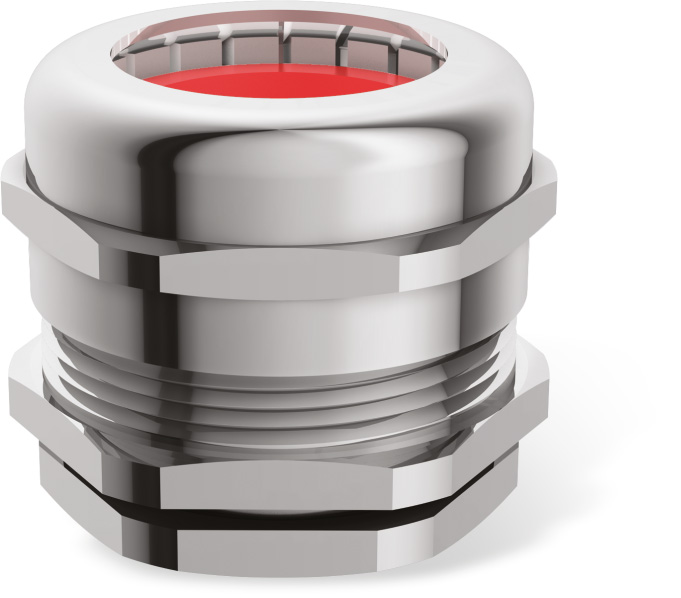

EMC Cable Gland Metric Threaded

Definition / Meaning of EMC Gland

EMC stands for Electromagnetic Compatibility

One of the important quality characteristics of electrical and electronic products is their electromagnetic compatibility (EMC).

To ensure a trouble-free operation of electrical appliances, systems, and plant, the basic EMC requirements must be met.

Electrical devices must be protected from interference and must not themselves interfere with other appliances and equipment.

Advantages of EMC Cable Glands:

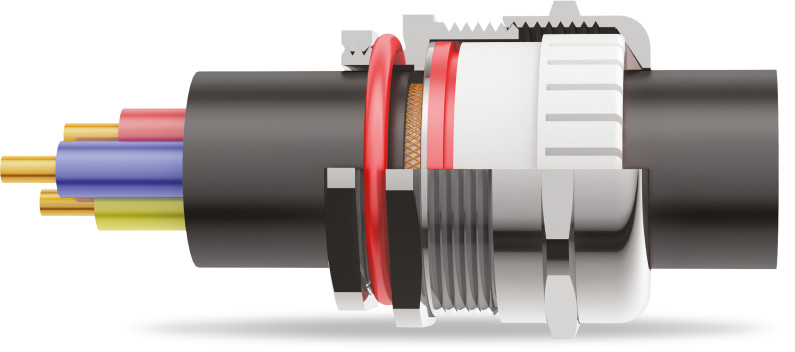

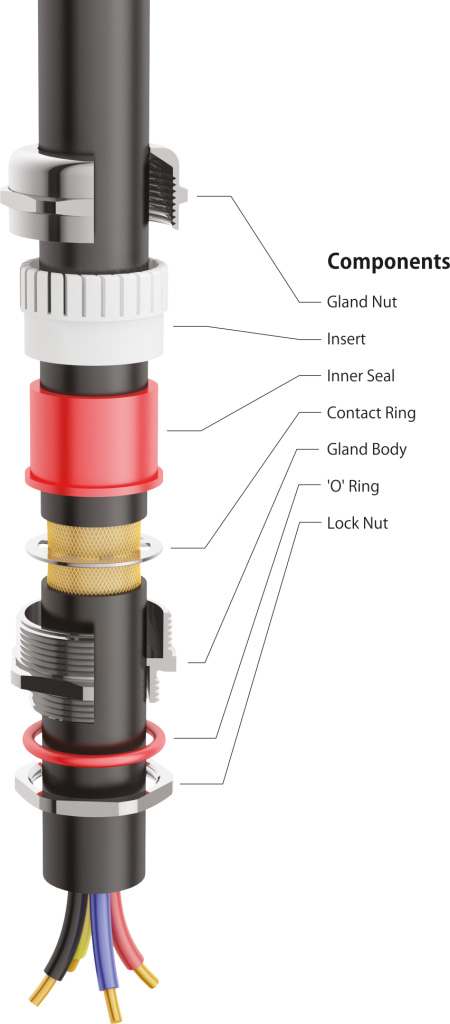

The EMC cable glands combine several advantages in one product.

- First, you get the same clamping ranges as the standard brass glands.

- The protection class is IP68.

- In order to get a low electrical impedance between the cable gland and the braiding of the cable the cable gland does not have to be disassembled.

- Perfect shielding will be achieved by just tightening the dome nut.

- The components are pre-assembled.

Applications of EMC Cable Glands:

It is widely used in the fields of:

- Electric Vehicles

- Electrical and Electronic Technologies

- Telecommunications

- Wireless Networking ODUs

- Power Supply switches, Motors, Distribution Box

- Solar PV Modules

- Lighting Display Devices

- Surveillance Cameras and many more devices

We are India's leading manufacturer, supplier, and exporter of Metric Threaded Single Compression EMC Cable Glands.

| Type | EMC Metric Threaded Single Compression Cable Gland |

|---|---|

| Gland Size | M12 to M63 |

| Gland Material | Brass (CuZn39Pb3), Stainless Steel 304, 316L |

| Thread | Metric |

| IP Rating | IP68 |

| Operating Temperature | Standard seals-20°C to +90°C |

| Cable Types | Unarmoured |

| Finish | Nickel Plated |

| Accessories | Matching Accessories available like PVS Shrouds, Lock Nuts & “O” Ring as per requirement |

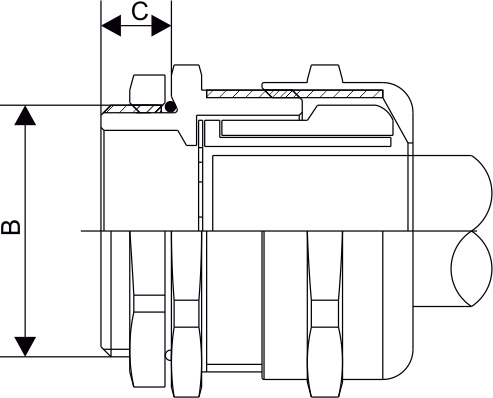

Size Chart / Specification

| CODE | CABLE SIZE | THREAD SIZE ‘B’ | THREAD LENGTH ‘C’ | ACROSS | CABLE RANGE “A” | ||

|---|---|---|---|---|---|---|---|

| METRIC | METRIC | SHORT | LONG | FLAT | MIN | MAX | |

| MM-M12-6.5E | M12 | M12 | 6 | 10 | 14.00 | 3.00 | 6.50 |

| MM-M12-8E | M12 | M12 | 6 | 10 | 17.00 | 4.00 | 8.00 |

| MM-M16-8E | M16 | M16 | 6 | 10 | 17.00 | 4.00 | 8.00 |

| MM-M16-10E | M16 | M16 | 6 | 10 | 20.00 | 6.00 | 10.00 |

| MM-M20-12E | M20 | M20 | 6.5 | 10 | 22.00 | 8.00 | 12.00 |

| MM-M20-14E | M20 | M20 | 6.5 | 10 | 24.00 | 10.00 | 14.00 |

| MM-M25-14E | M25 | M25 | 7 | 12 | 27.00 | 9.00 | 14.00 |

| MM-M25-16E | M25 | M25 | 7 | 12 | 27.00 | 11.00 | 16.00 |

| MM-M25-18E | M25 | M25 | 7 | 12 | 30.00 | 13.00 | 18.00 |

| MM-M32-20E | M32 | M32 | 8 | 12 | 40.00 | 13.00 | 20.00 |

| MM-M32-25E | M32 | M32 | 8 | 12 | 40.00 | 18.00 | 25.00 |

| MM-M40-23E | M40 | M40 | 8 | 15 | 44.00 | 15.00 | 23.00 |

| MM-M40-28E | M40 | M40 | 8 | 15 | 44.00 | 19.00 | 28.00 |

| MM-M40-32E | M40 | M40 | 8 | 15 | 50.00 | 22.00 | 32.00 |

| MM-M50-35E | M50 | M50 | 9 | 15 | 57.00 | 27.00 | 35.00 |

| MM-M50-38E | M50 | M50 | 9 | 15 | 57.00 | 32.00 | 38.00 |

| MM-M63-35E | M63 | M63 | 10 | 15 | 68.00 | 29.00 | 35.00 |

| MM-M63-44E | M63 | M63 | 10 | 15 | 68.00 | 37.00 | 44.00 |

| MATERIAL GRADE CONFIGURATIONS | |

|---|---|

| UL94V0 |

PVC Insert : Nylon 66 Rubber seal : Neoprene (FR) 0 Ring : Neoprene (FR) |

| High Temperature |

PVC Insert : PVDF Rubber seal : Viton 0 Ring : Viton |

| Regular Application |

PVC Insert : Nylon 6 Rubber seal : EPDM 0 Ring : NBR |